It is essential for the drilling units to be equipped with bulk tanks and surge tank monitoring system. Up to year 2005, hydraulic weighing gauges were used based on pressure transferred from load cells, typical manufacture like Martine Totco.

For disadvantage brought from hydraulic system, as low accuracy, dependent on maintenance and gap adjustment, individual display inconvenient for operators to monitors remotely, HICO developed long-life tank gauging system in 2004 and certificated by classification society. Currently£¬more than 100 sets have been used on varies drilling units, shore based bulk storage and treatment plants.

To meet the needs of clients, three configurations are developed and available for the clients:

1. Conventional level gauging system

Conventional level gauging system mainly used in high reliability, low accuracy or the upgrading project which is difficult to change the tank bracing structure. This system is much fit for the existing storage tank. Conventional level gauging system is widely applicable to upgrading project for drilling rigs. Nowadays, it has been gradually shrinking, as ash conveys gauging requires high accuracy.

2. Weighing gauging system based on electronics load celld

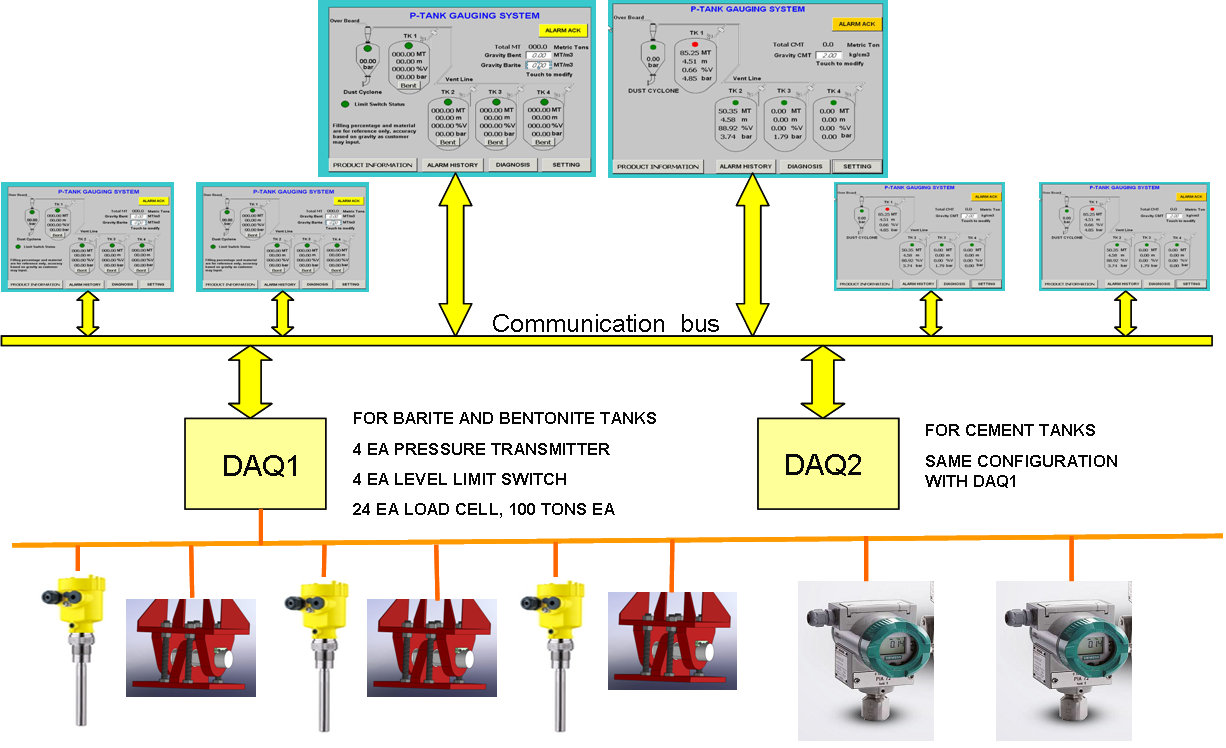

The high accurate load cells are used to measure the counter force at leg of bulk tanks. Together with pressure monitoring, high level alarm, PLC acquisition system, the system project whole information for the bulk system, and ease of data transmission avail the operator to monitor at a remote place or office.

3. Bulk Tank monitoring system integrated in remote bulk transferring system

For newly built offshore drilling units, we integrated the bulk system as whole, to make monitoring and manual/automatic transferring available, valve control cab be achieved automatically based on command for HMI, and weight&level information for each bulk tanks. The integrated system were used on many new built rigs, like JU2000-E, Cj46, CJ50, the systems have proven many praise for their high reliability, stability, ease of operation, and faultless products.

Main features:

- Comply with the codes of classification.

- HI quality components

- high-precision weighing sensor (up to 0.25% accuracy)

- Color touch screen are used as HMI for various information shown for user

- Remote operation function, makes work more simplified

- Pressure display and high level alarm for safety of operation

- On-line sensor calibration

- Alarm setting and alarm record function

- On-line failure diagnosis and on-line help menus

- Explosion-proof design is also available

Typical System£º

|