Tank Gauging System

Due to the characteristics of liquid storage on offshore oil drilling & production platforms and ships, such as scattered cabins, complex structures, installation limitations, corrosive measured media, liquid tank measurement has long been a difficult issue in the industry.

As earlier 2005, our company developed the TGS101 Platform Liquid Level Measurement System based on the cabin structure characteristics of drilling platforms and navigation ships, and obtained the CCS (China Classification Society) product certificate.

With more and more products have been equipped on different vessels, we have gradually formed a product system that represents advanced technology and practicality in the industry today. According to the characteristics of the platform or vessel, the system adopts a composite system integrating working principles such as ultrasonic, static pressure and air-bubbling, which enables reliable measurement of any irregularly shaped cabin. The liquid level signals of the cabins are collected, linearly compensated and processed in PLC (Programmable Logic Controller) programming, and tank liquid level, volume and sum of same kind are displayed at human-computer interfaces, for ease observation of the operators.

The TGS101 Liquid Level Measurement System is a fully customer-customized product, which can be redesigned and manufactured according to customers' requirement, ship types, numbers of tanks and display methods. The system can also be integrated with remote control valves and transfer pumps to achieve automatic operations, such as automatic ballasting and transferring, which will reduce manual workload significantly.

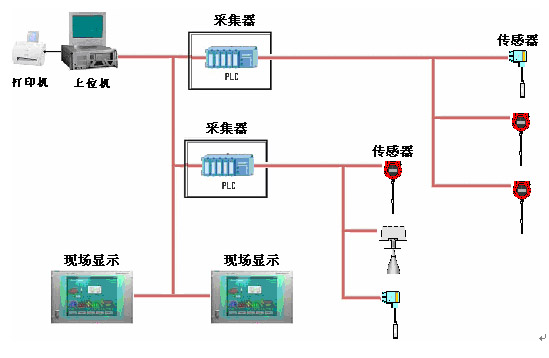

Our monitoring system is mainly composed of on-site sensors, data acquisation (PLC) and monitoring systems ( computers, touch screens, etc.). The structure is as follows:

1. System design

Based on the characteristic of scattered cabins on the vessels, the system is designed with a distributed control system (DCS) structure. On-site acquisition units are installed in close to the tanks to be monitored, and signals are transferred to the central control system via a network bus.

2.Human-Machine Interface (HMI)

The system utilizes on-site acquisition units to process and calculate the signals measured by level transducers, with the structural shape of the measured liquid tanks taken into account.

The processed results are then transferred to the touch screen or industrial computer through a communication network for remote display and monitoring. Operators can keep track of the real-time level changes of each tank, also calibration and alarm points setting can also be available.

Screen information at work station

a. Liquid levels of each tank

b. Volume of liquid

c. Weight of liquid in each tank with reference of gravity

d. Total volume and weight for liquid with same kind

e. Setting of calibration datas

f. Setting of alarm point

g. Control system monitors and online diagnosis

h. Daily report generation or periodical report generation

|